Decentralized WM takes the pain out of connecting your SAP ERP system to standalone Warehouse Management Systems, including third party applications and SAP WMS environments running in different SAP systems.

Solution Overview

Decentralized Warehouse Management constitutes an interface between SAP’s core modules (Materials management, sales and distribution, FI) and a warehouse management system, which can be another SAP system with WM implemented or a third party WMS solution. Information is passed directly via Intermediate Documents (IDocs) and Business Application Programming Interfaces (BAPIs). An IDoc is a data container with a predefined structure used to exchange information between SAP systems and the external world. A BAPI is a set of function modules grouped by business tasks.

• DWM is a fully integrated, cost-effective, flexible solution for connecting applications that perform warehouse management activities to applications that perform SAP ERP processes.

• Designed using standard SAP tools and functionality to provide data rich communication with WMS systems. This allows the Decentralized WM interface to be implemented relatively quickly.

• In addition, it is fully integrated with other SAP components. This gives users a seamless environment in which to transact their processes.

Functionality

Two types of data are exchanged between the systems: master data and transaction data. In a basic implementation of Decentralized WM, master data objects include materials, customers, and vendors. SAP ERP serves as the system of record for these objects, which is the primary location for maintaining most master data objects. Master data is passed to WM using standard Application Link Enabling (ALE) techniques such as change pointers. Depending on the particular needs of your implementation, you can transfer additional master data objects — such as batches and classes/characteristics — between systems as well.

The system calls BAPIs as changes are saved in inbound & outbound deliveries and posting changes.

Maintenance and Support

• The flexible interface allows you to tailor it to suit changing business requirements using customizing settings, rather than modify custom development.

• Decentralized WM requires little effort to maintain; maintenance steps usually involve troubleshooting IDoc errors related to improper master data settings.

Note: When a business is considering implementing Decentralized WM, there is often concern about losing data between the two systems, particularly if either the SAP ERP or WM system goes down. We have experienced both these events, as well as communication failure caused by networking issues. Data was not lost in any of these instances. The outbound transactions were captured and retained in the Remote Function Call (RFC) queues of the source system. Once a connection was reestablished between the two systems, the RFC entries were sent to the target system and the systems were re-synced.

WMS Process Overview

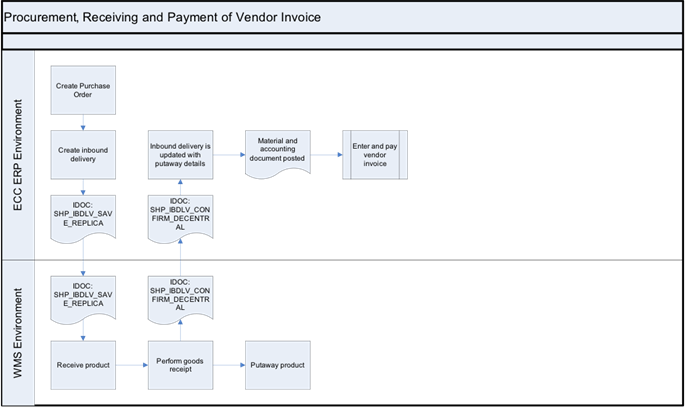

• Enter a purchase order in SAP ERP system. Demand planning and MRP tools are used to create purchase orders on the ERP system, or purchase orders can be created directly.

• Create Inbound Delivery in SAP ERP system. All transactions between the ERP system and the WMS system are communicated using deliveries. The inbound delivery can be created using Advanced Shipping Notifications from the vendor or created manually.

• Distribute the Inbound Delivery in the SAP ERP system. When the delivery is distributed, an IDoc is created that captures all the information in the IB DLV and replicates the data in the WMS environment.

• Receipt and Putaway in WMS Application. When product arrives from the vendor, it is inspected and received in the WMS application. The receipt triggers an IDoc message back to the SAP ERP system. The product is then stored in the warehouse.

• Post Goods Receipt in SAP ERP system. Details received from WMS are added to the inbound delivery and a goods receipt is posted. Material and accounting documents are created.

• Vendor Payment in SAP ERP system. The vendor’s invoice is entered in the system and the vendor is paid.

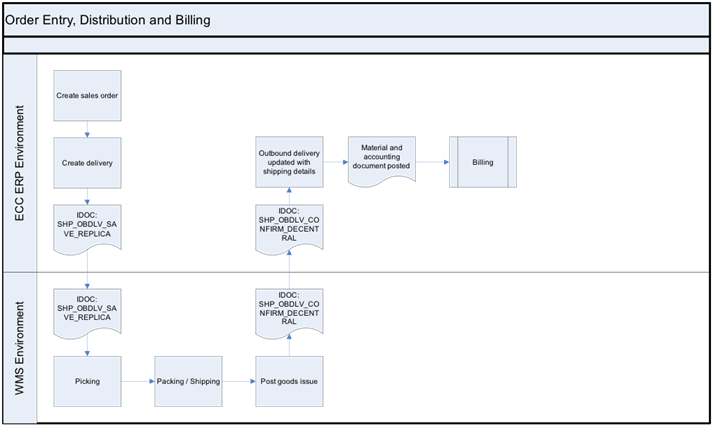

• Enter a sales order in SAP ERP system. A sales order is created using the existing order channels (web store, CRM, directly in ECC, etc.).

• Create Outbound Delivery in SAP ERP system. All transactions between the ERP system and the WMS system are communicated using deliveries. The outbound delivery can be created using the Delivery Due List or created manually for specific sales orders.

• Distribute the Outbound Delivery in the SAP ERP system. When the delivery is distributed, an IDoc is created that captures all the information in the OB DLV and replicates the data in the WMS environment.

• Pick product for deliveries in the WMS Application. Deliveries are created for sales orders. Pick tickets are generated for the deliveries and warehouse personnel physically pick items the warehouse.

• Pack product in the WMS Application. Next, the items are brought to a packing station and placed in a shipping carton. Note: See our Express Ship Solution for more details about shipping options – www.blueharbors.com/xsi.

• Post goods Issue in the WMS Application. A goods issue is posted for the delivery. The issue triggers an IDoc message back to the SAP ERP system.

• Post Goods Issue in SAP ERP system. Details received from WMS are added to the outbound delivery and a goods issue is posted. Material and accounting documents are created.

• Customer Invoicing in SAP ERP system. The customer invoice is generated.

DWM Case Study

Blue Harbors’ DWM solution helps a Specialty Distribution business unit at a large pharmaceutical distribution company improve distribution and operational efficiencies and enhance user experience and productivity with a single ERP interface. Read the full case study HERE.