Background

The Company’s Specialty Distribution services provide controlled access to specialty and oncology drugs through wholesale distribution. To increase operational efficiencies, the business made a decision to migrate distribution of these products to a different physical warehouse from the one that was currently being used. This alternate warehouse was already being managed using a different SAP system. As a result, the Specialty Distribution business unit would now be running on two separate SAP systems: sales transactions would continue to be captured on the current SAP system and deliveries would be subsequently processed from a warehouse that was managed on a different SAP system.

The Company turned to Blue Harbors to develop an interface that would allow them to transact Enterprise Resource Planning (ERP) processes (sales, purchasing, inventory management, and finance) in one SAP system, while performing the warehouse management processes in the second SAP system.

Blue Harbors’ DWM solution helps a Specialty Distribution business unit at a large pharmaceutical distribution company improve distribution and operational efficiencies and enhance user experience and productivity with a single ERP interface.

Challenges

In their existing SAP infrastructure, the Company’s business users responsible for ERP transactions were already working on an ECC version 5.0 SAP system and the operations users in the new warehouse were already working on an ECC version 6.0 SAP system. All sales and finance master data and history were stored in the ERP system. This type of scenario was not a new one for the Company. In the past custom interfaces were built between the ERP SAP system and the Warehousing Management System (WMS). The Company’s challenge was to ensure a smooth implementation so that the impact of shifting warehouses would be minimal for existing systems, the customers, and the business users.

Solution

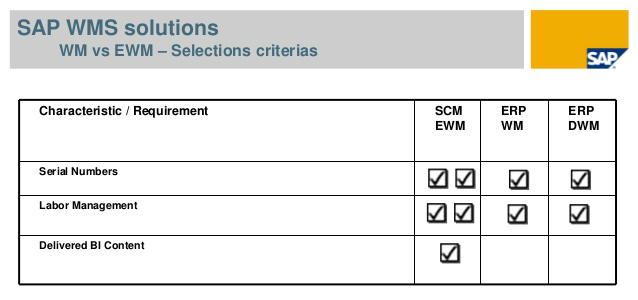

Blue Harbors first looked at existing SAP functionality that could be used right “out of the box”. We understood that the method SAP intended for this scenario was to utilize a suite of functionality called Decentralized Warehouse Management (DWM), a flexible interface that enables connecting an ERP SAP system to a WMS. This interface works particularly well when the WMS is also a SAP system. Because Blue Harbors has rolled out DWM multiple times, we were familiar with all aspects of the implementation.

Blue Harbors then built a prototype of the solution and demonstrated the functionality to the business. We emphasized that the solution would be much easier and faster to implement then building a custom program, and also showed how existing tools within SAP could be used to monitor the interface. We highlighted that supporting the DWM solution was straight forward compared with supporting a custom interface because DWM can be maintain using standard configuration rather than program code, enabling it to easily adapt to changing requirements from the business. Blue Harbors provided functional WM and ALE consulting resources and designed, built, tested, implemented, and supported the DWM solution.

Results

The results of the DWM Case Study? Greater productivity. While Operations required some training to learn a few new transactions in the DWM interface, there was no disruption experienced by the ERP users – their business processes and transactions remained unchanged. Both the ERP and WMS users worked as efficiently as before the switch. Additionally, a noticeable change was felt by the support staff. Prior to using the DWM interface, a custom interface was used. This interface required a lot of babysitting and often inventory quantities were out of sync between the ERP and WMS systems. These issues were resolved by the new DWM interface, since it is a robust system that ensures that master data and inventory quantities between the two systems always match.

Reduced operating expenses. Cost reduction was seen in two areas. First, the implementation time was improved because standard SAP functionally was utilized. Configuration and the time spent testing configuration progresses much more quickly than developing a custom interface and then testing it. Second, time spent with ongoing support issues is reduced because the DWM solution is tightly integrated with existing SAP interfacing tools (BAPIs and IDOCs) and monitoring tools. In addition, the mechanism for replicating master data and transaction data between the two systems happens natively, so there are no mapping issues transferring the data. The overall result was simplified maintenance without any third party applications or tools to enable communication between the two systems.

Improved user experience. DWM is tightly integrated with existing transactions with which the Company’s business users were already familiar with, making the interface nearly transparent to the user. The Company’s customer’s experience was improved because no new special processes are required on the operations side to distribute the pharmaceuticals, ensuring that execution is more consistent and that the customer experience is better.

Improved security and reliability. Because standard SAP functionality is supported by SAP, while custom programs are not, so this ensures that it is secure and reliable because it is backed by SAP.

The Company was so satisfied with the DWM solution that they have transitioned two more business programs onto it since the initial implementation, and they are actively looking for other opportunities to use this interface.

Please click here for more information on Blue Harbors Warehouse Management Solutions. For a RFP, please contact us by clicking here or email info@blueharbors.com.